-40%

YIHUA 3in1 Infrared Ray Hot Air BGA Rework Soldering Station Model 1000A 110V

$ 289.87

- Description

- Size Guide

Description

YIHUA 3in1 Infrared Ray Hot Air BGA Rework Soldering Station Model 1000A 110VFeature

1. Using the new

SAMSUNG microcomputer processor PID

programmable temperature control technology and uses an infrared source and optics to target heat to individual components without dislodging other SMT parts by way of eddies air currents.

2. Adopt infrared weld technology which independent exploration, infrared penetration strength, components uniform heating, beyond the traditional hot air heating vowed to prevent blow off the IC surrounding small components.

3. Technician focused infrared heat is easy to target most component removal/replacement and re-work.

4. Infrared heat source bulbs are long-lived, un-expensive and easily replaced.

5. Has bright delicate, low voltage LED lighting, safety and energy conservation.

6.It has External Sensor Temperature control mode, that is detected by the sensor IC surface temperature control temperature, this function is good for freshman operation ,it’s safe way protect components .

7.Surface Mount Technology (SMT) components 15-35cm in size.

8. This machine has 540W heating system , widely to 120mm*120mm.

9. Preheating plate color is black ,from the photics point of view, black color easy to absorb heating, shorten the warm-up time.

10. Powerful human function design, with the following functions:

A. Temperature correction function Correction of temperature range:-50°C~+50 °C(Infrared lamp analog value 580).

B. Celsius / Fahrenheit temperature display function

11. This machine also has soldering iron function, if you have the device ,you can used for all of the components solder ,desoldering ,preheating ,repair all components ,especially Micro BGA components.

Technical data

Voltage AC110V or AC220V±10%

Max power consumption 715W

Preheating station parts

Max power consumption: 540W

Light-emitting components:Far infrared heating plate

Temperature Range 50°C-300°C/122°F~572°F or 50 °C ~200 °C / 122°F~488°F

Display Type: LED

Preheating area 120*120mm

Infrared lamp part

Max power consumption: 150W

Light-emitting components Infrared emission lamp

Temperature Range 100°C-350°C/212°F~662°F

Temperature Stability ±1°C

Display Type LED

Effective irradiation area 35*35mm

Come with 2 lens cup, you can be choice two of lens cup from 28mm / 38mm /48mm.

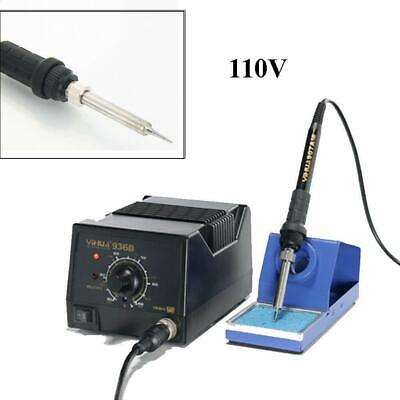

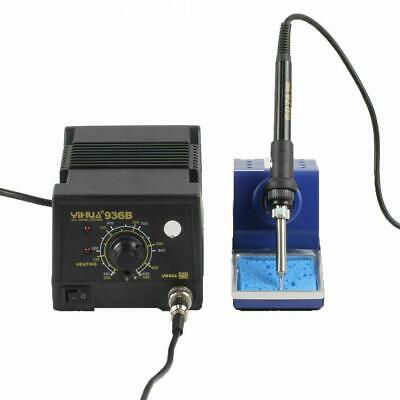

Soldering station part

Max power consumption: 75W

Heating components imported heater

Temperature Range 200°C-480°C/392°F~896°F

Temperature Stability ±1°C(

statics

)

T

ip of

ground

voltage <2mV

Tip ground impedanc

e

<2 ohm

Display Type LED Display

Handle cable length ≥

100cm

NOTICE

1.Repair circuit boards required precautions and necessary protective measures

1)To ensure that both sides of the circuit board preheat zone without fusible explosive flammable components,like Plastic,Display,Phone camera,LED,Electrolytic capacitors.

2)Ensure that no combustible fusible explosive components in Infrared light can shine on the area, If you can not avoid,Must use reflective paper keep out that. like Plastic,Display,Phone camera,LED,Electrolytic capacitors.

2.According to IC size, use a suitable diameter lamp cup(lamp cup size larger than IC size);Install lights Cup minimize the distance between lamp and IC,to facilitates heating.

3. Ensure that the working environment is no greater airflow to prevent heat loss,well sheltered measures when necessary.

4. Apply solder paste to the IC before the de-soldering,also you can early preheat then Apply solder paste,Especially BGA package IC,should be early preheat then apply solder paste,the can make solder paste penetrate into the bottom of the IC.

5. Wear heat protective gloves and goggles. Place the visor, good shading measures to protect the eyes.

6. Turn on the Infrared light power,set the temperature to about 280°C.Make the appropriate adjustments based on the size of the IC and circuit board. IC by infrared light irradiation will be rapidly warming (generally 1 to 3 minutes) .

7. Just started using this product, it is best to try to use the abandoned circuit board rework a few times. and so familiar with the use of this product ,then carry out normal maintenance work.

Usage

1. Suitable for de-soldering and soldering BGA, SOIC, CHIP, QFP, PLCC package SMD IC,

Particularly suitable for desoldering BGA module, computer motherboard north and south bridge,

all kinds of mobile phone motherboard SMT IC and LED lights.

2. Shrinking, Paint drying, adhesive removal, thawing, warming, Plastic welding etc.

Payment and Shipping

1) Payment

method

: PayPal, Credit Card,West Union

2)

The default delivery method is via ePacket, please kindly inform in advance if you have other preference

3) Lead time: 3 - 5 working days.

4) Shipping method: we will help to ship via FedEx, usually it takes 4-7 working days to arrive.

Warranty

The

guarantee

period is 1 year from the time of purchase and lifelong service support.

We will

provide online Q/A and troubleshooting support and technical advice service both workday or holidays.